Concrete Lifting

Concrete Lifting

A structure is only as good as the foundation it is built on. Regardless of how well-constructed a structure may be, most foundations eventually settle. Erosion, shifting soil, poor compaction, and many other environmental conditions tend to cause settling. These situations create significant problems for property owners and we are here to help you get them fixed.

Spray Polyurethane Foam is Your Best Solution

Among the most dependable products for jacking and leveling concrete slabs is Spray Polyurethane Foam. These two-component, high-strength, hydrophobic, structural foams serve as an extremely effective solution for residential, commercial, industrial, and agricultural applications. Our lifting foam expands up to 24 times its original volume to force its way into every void, leaving the sunken concrete firmly and evenly supported while lifting it back into place. Our foam cures to become as strong as crystalline bedrock and will not be subject to washing away like the original soil and is the permanent solution to sunken concrete.

Common Applications:

- Driveways

- Sidewalks

- Porches

- Patios

- Pool Decks

- Garage floors

- Slabs

- Warehouse Floors

- Roads and Highways

- Railroads

- Many More...

Why Concrete Slabs Settle and Crack:

Concrete settlement is common and can cause significant problems from pooling water, and cracks to more serious and costly issues such as trip hazards and liability issues. These are three common causes of concrete settlement.

First, concrete is often poured over recently backfilled soil around a home or building during new residential and commercial construction. The soil surrounding the newly poured foundation is often loose or poorly compacted, and it will settle over time - causing the concrete on top to crack and sink with it.

The second cause is the erosion of the soil under the slab. As water runs down through cracks and joints in the concrete foundation, it washes the soil out as it passes through. This creates voids under the concrete and eventually allows the concrete to settle. Once cracked, water incursion will inevitably lead to erosion under the concrete which could lead to further sinking.

The third cause for Concrete to settle is biological decay. Old tree stumps and roots or biodegradable materials in trash pits leftover from construction will decay over time leaving voids under slabs, causing concrete failure.

Concrete rarely sinks evenly, so cracks are likely to develop as one side sinks faster than the other.

FAQs

Erosion

Poor drainage, improperly placed downspouts, leaking drain pipes, and broken water lines are common culprits.

Poor Compaction

When backfilling on a job site, the contractor is supposed to compact the backfill by driving over it with heavy equipment. However, this isn’t always done properly for one reason or another.

Biological Decay

Construction trash pits, buried trees, and other biodegradable materials all break down. Sometimes structures are built over these areas.

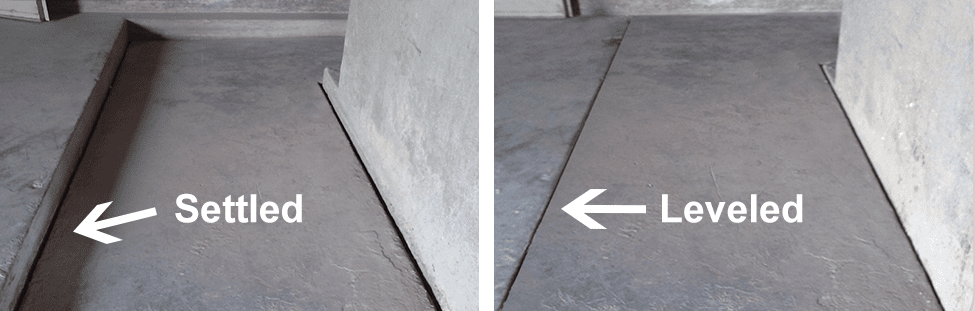

Lifts Slab Back to Level Height

Our Spray Polyurethane Foam usually allows us to raise slabs to within 1/10” of the desired height.

Reinforces Eroded Areas

Spray Polyurethane Foam displaces water and cures into a solid mass, completely reversing the erosion process.

Compacts the Soil

Spray Polyurethane Foam injection compacts loose soil to create a strong substrate.

Fills Voids Caused by Decay

Spray Polyurethane Foam fills voids before it cures, making it a great solution for instances of biological decay.

The Spray Polyurethane Foam we use is extremely safe and is environmentally friendly. Our foam is even approved for contact with drinking water (certified to NSF 61-5). That means they can be used anywhere without having an adverse effect on the environment and even on water quality. Our products have been rigorously tested for environmental compatibility which is critical to our commitment to assuring the safest and most cost-effective solution for our customers.

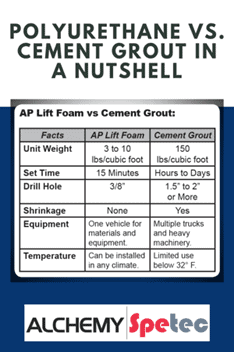

Use the Slab the Same Day as the Repair. Our spray polyurethane foam cures to 90% full strength in 15 minutes. In most cases, the site is ready for traffic and your business is up and running right after clean up.

Support for Up to 14,000 lbs./Sq. Ft. (That is 7 tons per square foot!). - The Spray Polyurethane Foams we use support a range of 7,200 - 14,000 pounds per square foot depending on which product you choose.

Lift and/or Stabilization Lasts for Decades! Our spray polyurethane foams are stronger than crystalline bedrock and will not wash away.

Injection holes are fewer and much smaller in diameter

Weighs less than 4 lbs. per cubic foot (compared to 150lbs of typical concrete)

It may be walked or driven on 15 minutes after installation

The material is waterproof and will never wash out

Expansive polymers (24X) allow lifting of heavier loads such as stoops and slab foundations

Restore Your Property Value

Real Estate professionals tell us that, in today’s market, it is difficult to sell a home with cracked and uneven concrete slabs (flatwork). Left untreated, a home's price may have to be reduced -- often by much more than the cost of the spray polyurethane foam repair. You should address your concrete leveling problems immediately to save money and avoid lengthy time-on-market scenarios. Most problems can be fixed quickly, and it all starts with a Free Estimate!

This is done by boring small 3/8-inch holes (smaller than a dime) in the slab and using specially designed equipment to inject a structural-grade polymer into the void. After the void is filled, the expanding properties of the Spray Polyurethane Foam allow for an accurate lift and leveling of the slab. Finally, the small holes are grouted and sealed, and the slab is completely restored.

This is done by boring small 3/8-inch holes (smaller than a dime) in the slab and using specially designed equipment to inject a structural-grade polymer into the void. After the void is filled, the expanding properties of the Spray Polyurethane Foam allow for an accurate lift and leveling of the slab. Finally, the small holes are grouted and sealed, and the slab is completely restored.